How to Cut Crown Molding with a Circular Saw Like a Pro

You pick up a beautiful piece of crown molding, ready to frame your ceiling with elegance. The excitement fades quickly when your first corner doesn’t meet — one side too long, the other too short, leaving an awkward gap.

Every beginner faces this challenge. Crown molding looks simple until you realize its angled design makes cutting far more complex than flat trim.

Unlike regular boards, crown molding sits diagonally between wall and ceiling, requiring precise miter and bevel cuts. Even a one-degree error can ruin alignment.

Imagine standing back to admire your work, only to see uneven corners that refuse to fit. It’s frustrating, especially when you’ve measured carefully.

The good news? With the right technique, a simple circular saw can create flawless joints. You don’t need an expensive miter saw — just precision and patience.

This guide will show you how to cut crown molding with a circular saw like a pro. You’ll learn how to set angles, position molding correctly, and make perfect inside and outside corners.

By the end, you’ll understand how to transform a basic room into an elegant, professional-looking space.

Let’s start by understanding the angles that make crown molding unique — and how to master them.

Understanding Crown Molding and Its Angles

Crown molding is decorative trim that bridges the corner where the wall meets the ceiling. It adds depth, elegance, and a finished look to any room.

Unlike flat trim, crown molding rests at an angle known as the spring angle. Common spring angles are 38°, 45°, and 52°.

This diagonal placement is what makes cutting tricky. You’re not just cutting straight — you’re cutting a combination of miter and bevel angles simultaneously.

If your angles are even slightly off, your corners won’t meet cleanly. That’s why accurate measuring and saw setup are crucial.

For standard inside corners, one piece overlaps the other to form a tight joint. The outside corners work oppositely — they wrap around outward.

Understanding which angle you’re cutting helps you set your saw properly. You’ll alternate between left-hand and right-hand cuts based on the corner type.

A small protractor or digital angle finder can help confirm your wall’s actual angle. Most walls aren’t perfectly 90°, so adjustments are often needed.

Precision here prevents frustration later during fitting and installation. Once you grasp these basic angles, cutting becomes far less intimidating.

The goal is to recreate that factory-smooth joint where two moldings meet seamlessly. It starts with knowing your angles inside out.

Tools and Materials You’ll Need

Cutting crown molding perfectly starts with using the right tools. A good setup ensures accuracy and safety throughout the process.

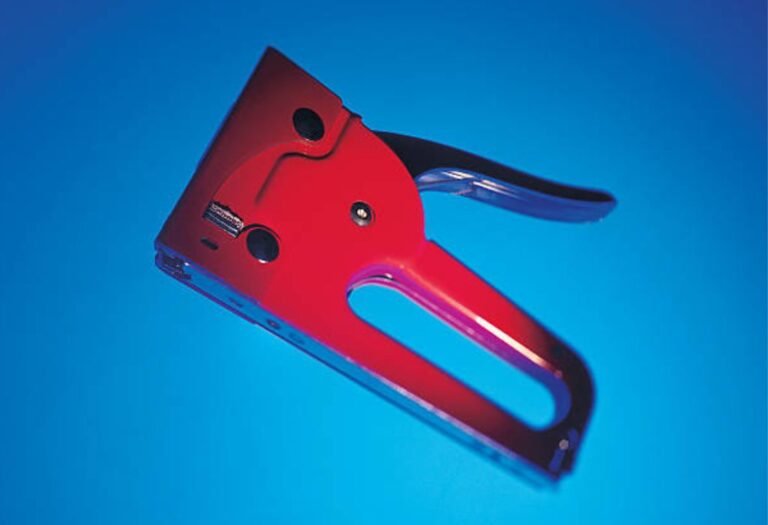

You’ll need a circular saw with adjustable bevel capability. Ensure it’s clean, sharp, and easy to handle.

Choose a fine-tooth crosscut or laminate blade with at least 60–80 teeth for smooth edges. Fewer teeth can cause splinters or rough finishes.

A miter box or guide rail helps maintain consistent cutting angles. It keeps your circular saw steady during angled cuts.

You’ll also need a measuring tape, pencil, clamps, safety goggles, ear protection, and a dust mask.

A speed square and angle finder are essential for transferring accurate corner angles to your molding.

If possible, use sawhorses or a stable table to support the molding pieces. Long trim requires even support to prevent bending.

Keep a fine-grit sandpaper handy for edge cleanup after cutting.

Having all tools within reach saves time and prevents mistakes during cutting. Preparation sets the tone for smooth, professional results.

Now that you’ve gathered everything, it’s time to set up your saw for perfect crown molding cuts.

Setting Up the Circular Saw for Crown Molding

Your circular saw must be set precisely before making any cuts. Incorrect settings will instantly ruin your joints.

First, unplug your saw and inspect the blade. It should be sharp, clean, and properly aligned.

Set the bevel angle to 45° for most standard crown molding cuts. You’ll adjust slightly if your wall isn’t perfectly square.

If your saw has miter adjustments, use 45° as a starting point for both inside and outside corners.

Check that your blade depth extends just below the molding’s thickness. Too deep cuts can cause tear-out.

Clamp your molding securely on a workbench or sawhorse before cutting. Stability prevents shifting during the cut.

Position the molding so the finished face is up and the bottom edge faces you. This mimics how it sits on the wall.

Make a few test cuts on scrap molding to confirm your setup. Fit the two pieces together and inspect for gaps.

If they don’t align perfectly, adjust the bevel angle slightly until they fit tight. Precision adjustments here ensure professional joints later.

Once everything looks good, lock your angles and prepare for real cuts.

Measuring and Marking the Molding Correctly

Accurate measurement is the foundation of clean joints. One wrong mark can waste a whole piece of molding.

Measure each wall segment carefully using a steel tape. Record exact lengths and label inside or outside corners.

Always mark your molding with the top and bottom clearly identified. Mixing them up leads to backward cuts.

Use a sharp pencil and light pressure to mark lines clearly without damaging the finish.

When measuring for inside corners, measure along the ceiling line. For outside corners, measure along the wall line.

Transfer the angle from the wall to your molding using an angle finder. This helps match the joint precisely.

Place small arrows showing the direction of the cut — left or right — to avoid confusion.

Double-check each mark before cutting. Many pros say, “Measure twice, cut once,” and it’s true for crown molding.

Cutting slightly long and trimming later is safer than cutting too short.

Careful marking eliminates guesswork and gives you consistent accuracy across all corners.

Positioning Crown Molding for Cutting

Crown molding must be positioned correctly to maintain its wall-ceiling orientation. This is called inverted cutting.

Place the molding upside down on your work surface so the ceiling edge rests on the base and the wall edge faces upward.

This simulates how it will sit when installed. Cutting it this way ensures the angles translate perfectly to real life.

Clamp the molding at this angle using small blocks or supports under one edge. It should match your molding’s spring angle exactly.

Make sure your molding doesn’t rock or shift during cutting. Movement leads to misaligned corners.

When cutting inside corners, the piece on the left fits the left wall; the right piece fits the right wall.

Label each piece before cutting multiple sections. Confusion during fitting wastes time and material.

Always align your saw blade just beside the marked line — not directly on it. This preserves exact measurement length.

Hold the saw firmly, let it reach full speed, and then guide it smoothly through the cut.

Proper positioning ensures your cuts are sharp, symmetrical, and easy to fit later.

How to Make Inside Corner Cuts

Inside corners are the most common and also the trickiest to get perfect. The two molding ends meet inward, forming a tight seam.

Start by identifying which side of the corner each piece belongs to. The right side piece will require an opposite angle from the left.

For the left-hand cut, set your saw to a 45° bevel leaning to the right. For the right-hand cut, tilt the saw to the left.

Keep the molding upside down in the cutting position. The top edge represents the ceiling line.

Make the first cut slowly, allowing the saw to slice cleanly through the molding.

After cutting both pieces, place them together on a flat surface to check alignment.

If there’s a small gap, lightly sand the ends or adjust your angle by one degree.

Avoid forcing pieces together — gentle sanding gives tighter joints.

Once satisfied, label these as “inside left” and “inside right” to avoid confusion later.

Inside corners are all about precision and patience — a single smooth pass creates perfection.

How to Make Outside Corner Cuts

Outside corners wrap outward instead of inward. They require mirrored cuts from inside corners.

The outside right-hand piece will have the bevel angled inward, while the left-hand piece will lean outward.

Keep your molding in the same inverted position during cutting. Consistency avoids orientation mistakes.

Mark your outside edges carefully since measurement error shows more visibly here.

Set the saw bevel to 45°, but double-check your direction before cutting.

Slowly guide the saw through the line without forcing pressure. Smooth motion ensures clean edges.

After both cuts, join them together on a flat surface and check for gaps.

If necessary, sand slightly for a seamless fit. Even a hairline adjustment can make corners meet perfectly.

Outside corners are visible and attract attention, so take your time aligning them.

Test-fit all pieces on the wall before final nailing — corrections are easier before installation.

Tips for Compound Angles and Irregular Walls

Not every wall is perfectly square, which complicates crown molding cuts. Older homes often have walls off by a few degrees.

Use a digital angle finder to measure the actual corner angle. Divide it by two to find the exact miter cut.

For instance, an 88° wall corner means each piece should be cut at 44°, not 45°.

Adjust your bevel slightly if your saw allows it. Even one degree makes a difference in the fit.

For compound angles, you’ll need both bevel and miter adjustments. This simulates how crown molding fits diagonally.

Test your cuts on scrap pieces first before cutting the actual molding.

Keep notes of each room’s angles so you can replicate settings consistently.

If a joint leaves a tiny gap, use caulk or wood filler for finishing.

Small imperfections are normal and can be corrected easily.

Proper measuring and test cuts guarantee your final installation looks seamless even on irregular walls.

Finishing Touches and Sanding the Edges

Once all pieces are cut, inspect each edge for small burrs or fibers. Smooth them gently with 220-grit sandpaper.

Avoid aggressive sanding that can round the sharp edge meant for tight joints.

For painted molding, caulk any visible seams along the corners after installation.

If you’re staining wood, apply filler before staining to maintain consistent color.

Use a small brush for fine touch-ups on corners and seams.

Lightly sand the ends where they meet to ensure perfect alignment before nailing.

If necessary, label all pieces in sequence for easy installation.

Apply a thin coat of primer or sealant to exposed edges before painting.

Take your time here — small finishing details make a big visual difference.

Clean edges and smooth joints elevate your project from amateur to professional.

Safety Tips for Cutting Crown Molding

Always wear safety goggles to protect your eyes from sawdust or splinters. Melamine and wood dust are harmful if inhaled.

Wear a dust mask and ear protection when cutting for extended periods. Circular saws are loud and produce fine dust.

Keep your fingers away from the spinning blade and use clamps instead of your hand to hold pieces.

Ensure your saw blade guard works smoothly before cutting. Never operate the saw with a stuck guard.

Maintain a balanced stance with firm footing throughout the cut.

Unplug the saw whenever adjusting bevel angles or changing the blade.

Check that all cords are positioned away from the cutting area.

Never rush or cut while tired — one mistake can cause injury.

Safety first always ensures your focus stays on precision, not panic.

Professional-quality work always begins with safe, careful practice.

Common Mistakes to Avoid

Cutting crown molding upside down incorrectly is the most common beginner mistake. Always verify which side represents the ceiling.

Rushing cuts without testing angles wastes material quickly. Always do trial cuts first.

Using a coarse-tooth blade tears the molding instead of slicing it cleanly. Choose fine teeth every time.

Skipping measurements between inside and outside corners leads to mismatched lengths.

Forgetting to label pieces creates confusion during installation.

Not supporting long molding pieces causes bending and uneven cuts.

Over-sanding the ends can create uneven joints that won’t close properly.

Ignoring wall irregularities leads to visible gaps at corners.

Applying too much force on the saw causes vibration and burns the surface.

Avoiding these mistakes makes cutting smoother and installation effortless.

Pro Tips for Perfect Miter Joints

Cut both corner pieces from the same length of molding to ensure color and pattern match.

Always cut slightly long and trim down to fit perfectly.

Use a scrap piece to test saw settings before the real cut.

Hold the saw steady and let it reach full speed before contact.

Check fitment immediately after cutting and make minor corrections.

Mark each piece’s orientation (top, bottom, wall, ceiling) to stay consistent.

Use wood glue at joints before nailing for stronger bonds.

Keep a steady hand — consistency in pressure prevents uneven bevels.

Clean your saw blade regularly to avoid residue buildup.

These small habits transform your work from decent to professional-grade craftsmanship.

Frequently Asked Questions

Can I cut crown molding without a miter saw?

Yes, a circular saw works perfectly if you set accurate bevel angles and use a guide.

What angle should I cut crown molding corners?

Usually 45°, but confirm with an angle finder — some walls may need slight adjustments.

Should I cut crown molding face up or face down?

Cut it upside down so the top edge mimics its ceiling position.

What blade is best for clean cuts?

A fine-tooth carbide or crosscut blade with at least 60–80 teeth.

How do I fix small gaps between corners?

Use fine sandpaper, caulk, or wood filler before painting.

Can I use a jigsaw instead of a circular saw?

Only for small touch-ups — jigsaws aren’t ideal for long precision cuts.

How do I measure for inside vs outside corners?

Measure along the ceiling for inside corners and along the wall for outside corners.

Should I nail molding before painting?

Yes, nail it first, then caulk and paint for the best finish.

Can I use a laser level for alignment?

Absolutely — it helps maintain a straight, even line across long walls.

What’s the easiest way to cut compound angles?

Use a digital angle finder and adjust bevel plus miter together for accuracy.

Conclusion

Cutting crown molding with a circular saw may seem challenging at first, but it’s entirely achievable with patience and practice. Each accurate angle and steady motion brings you closer to professional-quality results.

The secret lies in preparation — measuring carefully, setting the right bevel, and maintaining steady control. Even without a miter saw, you can create perfect corners every time.

Remember to cut inverted, test on scraps, and always support long pieces properly. These habits ensure precision from start to finish.

Once you master this technique, every corner in your room will meet perfectly, reflecting true craftsmanship.

Crown molding is more than decoration — it’s a detail that transforms ordinary walls into elegant interiors. With your new cutting skills, that professional touch is now within reach.

So measure twice, cut confidently, and enjoy the satisfaction of seeing seamless joints and smooth, graceful lines along your ceiling.

I’m Michael R. Turner, the founder, lead writer, and passionate DIY enthusiast behind 101diytools.com. With years of hands-on experience in home improvement and power tools, I built this platform to share practical tips, in-depth guides, and honest reviews to help DIYers of all skill levels tackle projects with confidence and the right tools.