How Powerful Is a Circular Saw Motor?

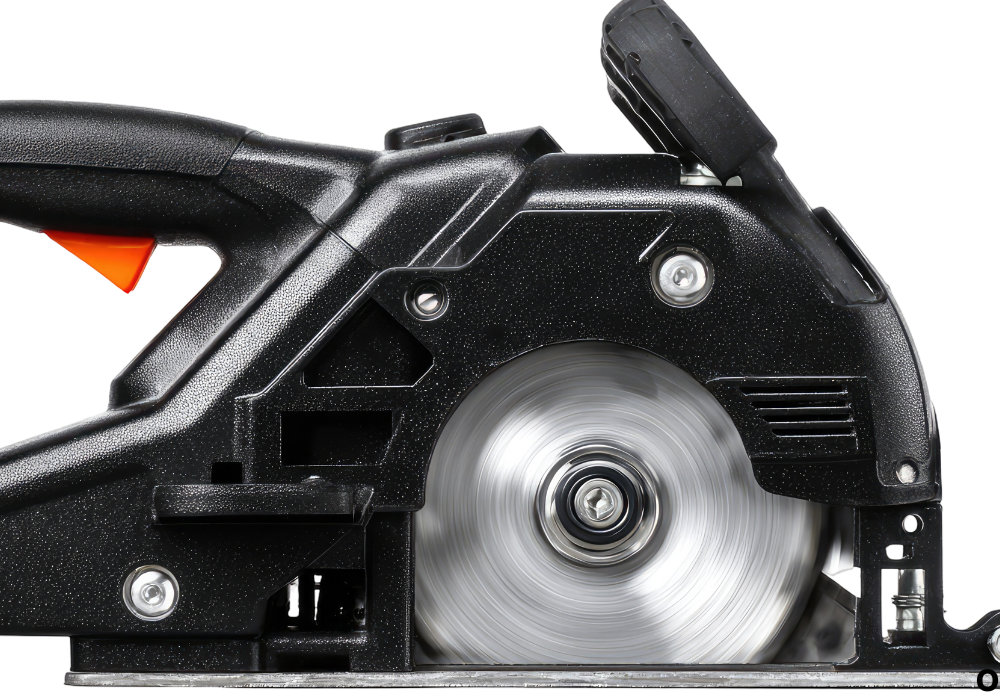

Imagine standing in your workshop as the sharp whir of a circular saw fills the air. The blade spins effortlessly through a piece of lumber, leaving behind a perfect, clean edge.

That power you feel comes from the heart of the tool — the motor. It’s the engine that determines how fast the blade spins, how deep it cuts, and how easily it handles tough materials.

Circular saws may look simple, but their motor power defines everything from cutting performance to durability and precision. A stronger motor means smoother cuts, less strain, and longer tool life.

According to a 2024 tool industry survey, over 70 percent of professional woodworkers choose their saws based primarily on motor performance rather than blade type or design.

In this article, we’ll explore how powerful a circular saw motor really is, what affects its performance, and how to choose the right power level for your woodworking projects.

Understanding Circular Saw Motor Power

Every circular saw is driven by a motor that converts electrical or battery energy into rotational force. This force, known as torque, determines how efficiently the saw blade cuts through wood, metal, or plastic.

Motor power is usually measured in amperage (amps) for corded saws and voltage (volts) for cordless ones. Higher numbers generally mean more cutting strength and endurance.

Most corded circular saws operate between 13 and 15 amps, which equals roughly 1,600 to 2,000 watts of power. Cordless models typically range from 18V to 60V, depending on their battery systems.

The motor type also affects efficiency. Traditional brushed motors generate more friction and heat, while modern brushless motors use electronic control for cooler, more consistent performance.

Together, voltage, current, and motor design determine how powerful a circular saw feels in your hands.

Corded vs Cordless Motor Power

Corded circular saws draw constant current from an electrical outlet, giving them steady power and higher torque. They’re often rated between 1,500 and 2,400 watts, capable of slicing through dense hardwoods with ease.

Cordless saws rely on rechargeable batteries, and their power depends on voltage and amp-hour (Ah) ratings. An 18V 5.0Ah battery delivers moderate power for general use, while a 36V or 60V system rivals corded strength.

Corded motors rarely bog down since they don’t rely on stored energy. Cordless motors, however, can slow slightly under heavy load if the battery charge drops.

Modern brushless cordless motors have closed that gap dramatically. Many 18V and 36V brushless systems now match 15-amp corded saws in both torque and cutting speed.

The choice comes down to convenience versus unlimited runtime: corded for power consistency, cordless for portability and freedom.

How Horsepower and Torque Work Together

Motor strength isn’t just about amps or volts — it’s also about horsepower (HP) and torque (Nm). Horsepower measures the rate of work, while torque measures twisting force.

In circular saws, torque determines how easily the blade keeps spinning under load. High torque prevents bogging down when cutting thick or dense wood.

Horsepower, on the other hand, reflects overall cutting capacity and efficiency. A typical 15-amp circular saw motor generates around 2 to 2.5 horsepower.

The perfect combination of torque and speed ensures a clean, smooth cut without overheating or burning the wood.

Professional-grade saws often feature high-torque motors designed to maintain consistent RPM even through knots or pressure-treated lumber.

The Role of RPM in Motor Performance

The RPM (revolutions per minute) rating tells you how fast the blade spins. Faster isn’t always better, but it’s important for efficiency.

Most standard circular saws operate between 4,000 and 6,000 RPM, depending on the design. Lightweight saws tend to have higher RPM but less torque, while heavy-duty models trade speed for cutting strength.

A faster blade spins smoothly through thin or soft materials, while a slower, high-torque saw performs better on thick or wet lumber.

Maintaining RPM under load is a sign of motor strength. Weak motors lose speed quickly when faced with resistance, producing rougher cuts.

High-quality saws with stable RPM under pressure indicate an efficient, well-balanced motor design.

Types of Motors Used in Circular Saws

Circular saws use one of two main motor designs: universal motors and brushless motors.

Universal motors are found in most corded models. They provide strong torque and high RPM but tend to be noisier and require more maintenance.

Brushless motors dominate modern cordless saws. They use electronic controllers to deliver power precisely, reducing energy loss and extending battery life.

Brushless motors also adapt power output based on resistance. This means they automatically increase torque when cutting dense wood and reduce power when cutting soft material.

This intelligence allows brushless circular saws to outperform older brushed designs in both speed and efficiency.

How Power Affects Cutting Depth and Material Handling

The stronger the motor, the more versatile the saw becomes. A high-power motor can maintain steady speed while cutting through hardwood, plastic, or even thin metals.

With a 15-amp corded saw, you can expect cutting depths of 2½ inches at 90 degrees and 1¾ inches at 45 degrees using a 7¼-inch blade.

Lower-power 10-amp saws might struggle to maintain speed at those depths, especially in hardwoods like oak or maple.

Cordless saws above 36V perform similarly, offering near-corded results in performance and accuracy.

For deep or angled cuts, stronger motors reduce vibration and make the tool safer and easier to control.

How to Choose the Right Motor Power

Choosing the right circular saw motor depends on the materials you cut and how often you work.

For light DIY or occasional use, a 12- to 13-amp corded saw or an 18V cordless model works perfectly. They’re lightweight, affordable, and adequate for plywood or softwood.

For daily professional use, a 15-amp corded saw or a 36V brushless cordless saw is ideal for consistent performance under load.

If you often cut thick beams, pressure-treated wood, or concrete boards, focus on torque and blade size instead of just amperage.

Always pair your motor power with sharp, high-quality blades designed for the materials you work with to achieve optimal results.

The Future of Circular Saw Motors

Advancements in battery and motor technology are changing how circular saws are built. Brushless designs are now the standard for both corded and cordless models.

New motor systems use smart sensors to automatically regulate speed and torque based on resistance. This means smoother performance and less user fatigue.

Lithium-ion batteries with higher voltage and capacity now deliver power once limited to corded saws. Some 60V cordless systems generate up to 2.5 horsepower equivalent, enough for professional framing or construction.

Manufacturers are also integrating thermal protection systems and electronic brakes to extend motor life and enhance safety.

The result is a new generation of saws that are more powerful, efficient, and durable than ever before.

Market Insights and Statistics

According to recent industry data, the global circular saw market exceeded $11 billion in 2024, with over 45 percent of sales coming from cordless models.

Brushless motors account for nearly 70 percent of new power-tool launches, reflecting the demand for energy-efficient systems.

Professional users cite motor performance and torque consistency as the top two reasons for brand loyalty.

Experts predict that by 2030, smart-controlled circular saws will dominate both consumer and professional markets.

This evolution shows how vital motor technology has become in shaping the performance of modern power tools.

FAQs

1. How powerful should a circular saw motor be?

For most woodworking, a 15-amp corded motor or a 36V brushless cordless motor provides sufficient power for smooth, accurate cuts.

2. What does 15 amps mean on a saw motor?

It means the motor draws 15 amps of electrical current, which typically equals about 2 horsepower of output power.

3. Are cordless saw motors weaker than corded ones?

Not anymore. Modern 36V and 60V brushless cordless saws now rival corded saws in torque and cutting speed.

4. Does a higher RPM always mean more power?

No. RPM measures speed, not torque. A balanced combination of RPM and torque produces the best cutting results.

5. How can I tell if a saw has enough power for my work?

Check the amp or voltage rating and test its performance on dense wood. A strong saw maintains speed without slowing or stalling.

6. What’s better for durability: brushed or brushless motor?

Brushless motors last longer, generate less heat, and require less maintenance than brushed designs.

7. Can motor power affect safety?

Yes. Weak motors can stall and kick back, while overly powerful ones need strong control. Always match motor strength to your skill level.

Conclusion

A circular saw’s motor is the true measure of its strength and performance. It determines how cleanly and efficiently you can cut through materials of all kinds.

Powerful motors maintain speed under load, reduce vibration, and produce smoother cuts with less effort. Choosing the right balance of torque, RPM, and design can transform how you work.

Whether you’re a hobbyist using a 12-amp saw or a pro relying on a 15-amp powerhouse, understanding motor power helps you get the most from your tool.

In the end, the most powerful circular saw isn’t just about numbers — it’s about precision, balance, and how confidently it lets you create every cut.

I’m Michael R. Turner, the founder, lead writer, and passionate DIY enthusiast behind 101diytools.com. With years of hands-on experience in home improvement and power tools, I built this platform to share practical tips, in-depth guides, and honest reviews to help DIYers of all skill levels tackle projects with confidence and the right tools.