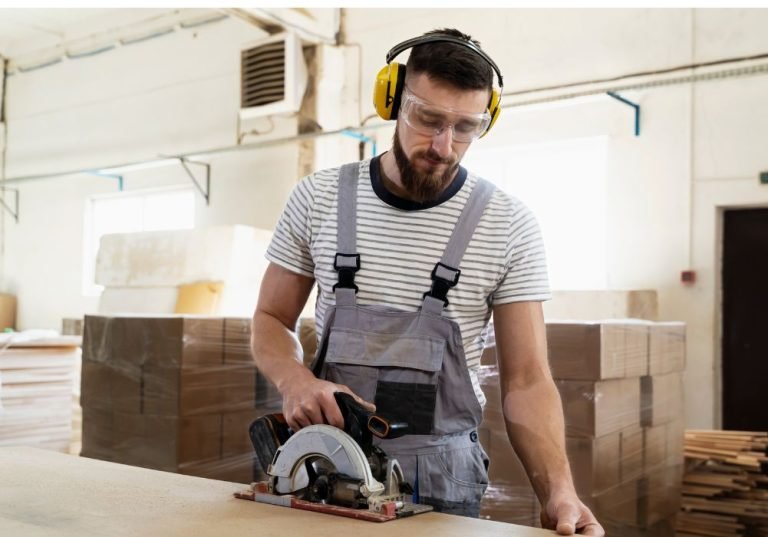

How Deep Should a Circular Saw Blade Be Set

You pick up your circular saw, mark the wood, and begin cutting — but the blade struggles, smokes, or splinters the surface. You check your alignment, thinking it’s the wood, but the real culprit is your blade depth.

Every DIYer and woodworker faces this hidden issue at some point. Setting your circular saw blade too deep or too shallow can ruin a perfect cut.

When the depth is wrong, the saw fights back, creating more resistance and kickback risks. Too shallow, and the blade barely bites the surface, leaving burn marks and uneven lines.

Imagine cutting plywood for a project, but the saw vibrates and leaves jagged edges. Frustration rises because it feels like the tool is working against you.

The truth is, blade depth directly controls precision, safety, and cutting efficiency. Professionals know that even a quarter-inch adjustment can make or break the result.

This guide will show you exactly how deep to set your circular saw blade for clean, safe, and effortless cuts.

By the end, you’ll understand the science, safety, and technique behind the perfect blade setup. Let’s begin with why blade depth matters more than most people realize.

Why Blade Depth Matters

Blade depth isn’t just about how far the teeth stick out — it determines how the saw interacts with the wood. The right depth gives smoother, faster, and safer results.

When your blade is set too deep, more teeth contact the wood at once, causing more friction. This makes the saw work harder and heat up faster.

Too shallow, and the blade doesn’t clear the wood fibers cleanly. It burns, binds, or stalls mid-cut.

A properly set depth minimizes stress on the motor while maintaining control and smooth movement.

The ideal cutting depth allows the bottom of the blade’s teeth to extend about ¼ inch below the material. This gives just enough clearance for clean slicing.

Shallow settings are safer and create less kickback. Deep settings often grab the material and can cause jerky motions.

Cutting efficiency improves dramatically when depth is correct. You’ll notice quieter operation and less vibration.

Consistent blade depth also helps maintain even wear across the teeth. This extends the life of your saw and blades.

In short, the right depth saves energy, boosts precision, and makes cutting feel effortless. Understanding this principle is the foundation of every professional cut.

Understanding the Cutting Mechanics of a Circular Saw

To understand blade depth, you need to know how a circular saw cuts. Each tooth enters and exits the material at a specific angle.

When set correctly, only a few teeth cut at once, reducing drag and heat. This ensures a clean line without burning or rough edges.

If the blade goes too deep, too many teeth engage the wood. The saw struggles to maintain speed, creating rough, uneven cuts.

This also increases kickback risk because the wood pinches against the blade. Kickback happens when the blade binds and jerks the saw upward.

A shallow depth, on the other hand, doesn’t give the blade enough bite. It rides the surface instead of cutting through smoothly.

The ¼-inch rule gives the perfect compromise between bite and control. It allows teeth to cleanly exit the cut without tearing fibers.

At this depth, wood chips eject cleanly, and the motor maintains steady speed.

Professional carpenters use this method for everything from plywood to hardwood. It’s a universal safety and performance standard.

Understanding this balance transforms how your circular saw feels in hand. The tool becomes smoother, quieter, and far easier to control.

Ideal Blade Depth for Different Materials

Not every material needs the same blade depth. While ¼ inch is ideal for general cuts, some materials require small adjustments.

For plywood or MDF, ¼ inch is perfect because it minimizes tear-out and keeps the surface clean.

For thicker hardwoods, you can go slightly deeper — about ⅜ inch — to allow the blade to pass cleanly without overheating.

When cutting softwoods like pine, a shallow ¼ inch is still best. Too deep will tear the soft grain and cause splintering.

If you’re cutting laminate or melamine, precise shallow depth and fine-tooth blades work best to avoid chips.

For composite boards, avoid setting the blade too deep since it dulls the teeth quickly.

In cases of cross-cutting thicker planks, make multiple shallow passes instead of one deep cut.

Using the correct depth for each material type prevents burning and keeps the cut line neat.

Always remember: less is more. A shallow setting increases control and safety for nearly every situation.

With a little practice, you’ll instinctively know how deep to go for each project material.

How to Measure and Set the Correct Blade Depth

Setting blade depth is simple, but precision matters. First, unplug your circular saw before making any adjustments.

Place your saw beside the material you’re cutting. Lower the blade until the tip of one tooth extends about ¼ inch below the board.

Tighten the depth lever securely to lock this position. Make sure the lever feels snug and stable before cutting.

If your saw has a depth scale, double-check it visually for accuracy. Some older models may have worn markings.

It’s also helpful to test on a scrap piece before cutting your main material. This ensures your setup feels right.

When adjusting depth, keep the saw upright and avoid touching the blade. The teeth are extremely sharp, even when stationary.

If your project involves multiple boards of varying thickness, reset depth for each one. Don’t assume one setting fits all.

Once set, verify blade alignment by lowering it fully through the cut zone. It should clear the wood smoothly with no drag.

Proper setup takes less than a minute but guarantees professional-level precision. The time you save in rework is worth the care.

Common Problems from Wrong Blade Depth

Using the wrong blade depth causes more damage than most realize. A too-deep blade wastes energy, dulls faster, and risks injury.

When the blade cuts too deep, it pulls harder on the motor, causing strain and slower RPMs. This leads to burning and rough finishes.

It also increases the chance of kickback since more blade surface engages the wood.

If the depth is too shallow, the saw skims the surface and fails to cut evenly. You’ll notice scorching or skipping along the line.

Incorrect depth also causes splintering, especially near the exit side of the cut.

Over time, improper settings reduce the lifespan of both the blade and the saw bearings.

The cut line may wander because the blade struggles to stay on course. Excessive vibration also tires your hands and arms quickly.

Another issue is material tear-out, especially when cutting veneered or laminated boards.

By maintaining correct depth, you protect your tool, your workpiece, and yourself. Precision here means smoother, faster, safer results.

Safety Tips When Adjusting Circular Saw Depth

Safety always comes before speed. Adjusting blade depth requires caution and focus.

Always unplug the saw before touching any part of the blade. Even small accidental starts can cause injury.

Work on a stable surface so the saw doesn’t slip while adjusting.

Wear safety gloves if possible to protect against sharp teeth.

Ensure your blade guard moves freely and returns automatically after lifting.

Double-check that the depth lock lever is tight and secure before cutting.

Position yourself slightly to the side when cutting to avoid potential kickback.

Never adjust depth while the saw is running or plugged in.

Perform a test cut first to verify accuracy before proceeding with the main piece.

Small safety habits like these build long-term confidence and professionalism in woodworking.

Signs You’re Using the Wrong Depth

Your saw often tells you when depth is off. The most common sign is rough, uneven edges after cutting.

If the saw feels heavy or struggles, the blade is likely too deep.

You might also notice burning or smoke along the cut line. This means too much friction from excessive contact.

If the blade skips or doesn’t penetrate fully, it’s too shallow.

Tear-out and chipping on the underside often mean you’re cutting too deep without proper support.

A loud, whining sound usually signals over-engagement with the wood.

Frequent kickbacks or jerky motion suggest improper setup or depth locking.

Check for vibration — if your saw feels shaky, adjust the depth slightly upward.

Consistent clean cuts mean you’ve found the perfect depth. Once you feel it, you’ll recognize it instantly on future projects.

Advanced Tips for Smooth and Accurate Cuts

Always begin with a shallow scoring pass on delicate materials. This defines the line and prevents splintering.

Maintain a firm, steady feed rate throughout the cut — not too fast, not too slow.

Use a guide rail or straightedge for precise alignment, especially on long cuts.

Keep your blade sharp and clean; dull blades make depth adjustments useless.

When cutting thick boards, make multiple shallow passes rather than one deep one.

Check the base plate regularly to ensure it sits flat against the surface.

A consistent angle and proper pressure make every cut look machine-perfect.

Practice on scrap wood before cutting expensive material.

Avoid forcing the saw; let the blade do the work smoothly.

These small professional habits make your results sharp, clean, and accurate every time.

Maintenance and Calibration of Depth Adjustments

A dirty or stiff depth mechanism can throw off your accuracy. Clean your saw regularly, especially around the depth pivot area.

Use compressed air or a small brush to remove dust buildup.

Lubricate the adjustment lever with light machine oil to keep movement smooth.

Check the depth scale markings for wear and recalibrate if needed.

Some saws allow you to reset depth stops — use a ruler to verify real depth.

Inspect the base plate screws and ensure they’re tight. Loose parts cause uneven cuts.

Occasionally check the angle adjustment too, as misalignment affects perceived depth.

When storing your saw, lock the blade in a shallow position to relieve spring tension.

Periodic maintenance keeps your saw precise and reliable for years. A well-calibrated depth lever saves you constant readjustments.

When to Re-Adjust Blade Depth Mid-Project

Some projects involve boards of varying thicknesses. Always adjust blade depth between cuts to match the new material.

If switching from ¾-inch plywood to 1½-inch lumber, reset your blade for deeper cuts.

Cutting thin trim after thick planks without adjustment causes tear-out and poor edges.

When cutting bevels, remember that blade depth changes with the angle. Adjust before every bevel cut.

Always recheck after moving your saw between workstations. Bumps or vibrations can shift the lever slightly.

If you notice resistance or burning mid-project, pause and inspect the depth setting.

Even small shifts in depth affect accuracy dramatically.

Getting into the habit of rechecking depth ensures consistent professional results.

This step takes seconds but eliminates rework and frustration later.

Common Myths About Blade Depth Settings

Many believe deeper blade settings mean faster cuts, but that’s false. Deep cuts slow the motor and reduce precision.

Another myth is that one blade depth works for all materials. Each wood type reacts differently under pressure.

Some think shallow settings wear the blade faster — in truth, deep cuts cause faster dulling.

Another misconception is that depth doesn’t affect safety. In fact, improper settings are a leading cause of kickback.

People also assume that saw power compensates for bad depth. No motor can overcome poor setup.

Believing “it looks fine” is also misleading; visual judgment often fails for precision work.

Following depth guides and measuring each time ensures consistent accuracy.

Correcting these myths helps you build smarter, safer cutting habits.

Experience and technique always outperform force and speed.

Frequently Asked Questions

How far should a circular saw blade stick out below the board?

About ¼ inch below the material surface — this gives the best balance between power and control.

What happens if the blade is set too deep?

It increases kickback risk, burns wood, and dulls the blade quickly.

What if my blade is too shallow?

The saw will struggle, skip, or leave incomplete cuts with scorch marks.

Do I need to reset depth for each material?

Yes, always match blade depth to the thickness and hardness of each wood type.

How do I know if the depth is right?

You should see a smooth cut, minimal vibration, and no burning or chipping.

Can I use one setting for all projects?

No, because material thickness and density vary; always check depth manually.

Does blade depth affect safety?

Absolutely — deeper settings increase kickback and reduce control.

Should I make test cuts before starting?

Yes, testing on scrap wood helps confirm depth accuracy.

Can the wrong depth damage the saw?

Yes, excessive strain wears out bearings, the motor, and blade teeth faster.

What tools help measure depth precisely?

A simple ruler, depth gauge, or your saw’s built-in scale can do the job accurately.

Conclusion

Setting your circular saw blade to the correct depth is the foundation of clean, professional cuts. The difference between rough edges and perfect precision often lies within a single quarter inch.

The ideal setup keeps your blade about ¼ inch below the wood surface — shallow enough for safety, deep enough for power.

Proper blade depth ensures smoother operation, reduces kickback, and extends the life of your tools. It’s a small detail with a huge impact on your results.

Whether cutting plywood, hardwood, or laminate, take a moment to measure and adjust. The payoff is consistent, beautiful work every time.

Avoid the common myth that “deeper cuts are better” — precision always beats power.

By following these guidelines, you’ll master one of the most overlooked skills in woodworking.

Every cut you make will feel easier, safer, and more satisfying. With the right blade depth, your circular saw becomes an extension of your skill — not a source of struggle.

I’m Michael R. Turner, the founder, lead writer, and passionate DIY enthusiast behind 101diytools.com. With years of hands-on experience in home improvement and power tools, I built this platform to share practical tips, in-depth guides, and honest reviews to help DIYers of all skill levels tackle projects with confidence and the right tools.