What Type of Gloves for Electrical Work Keep You Safe

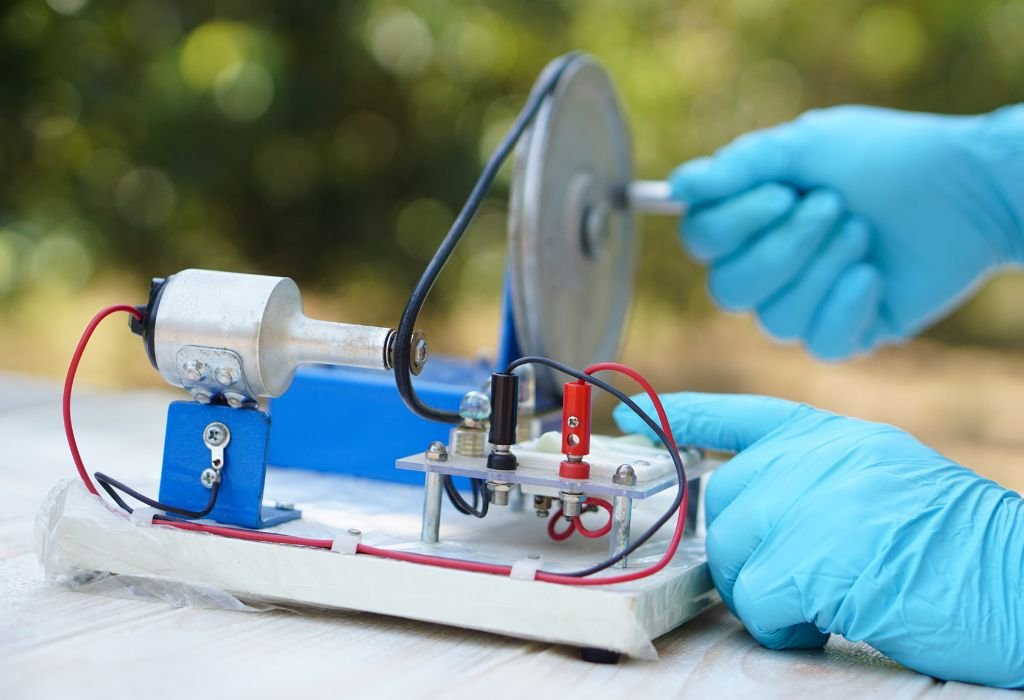

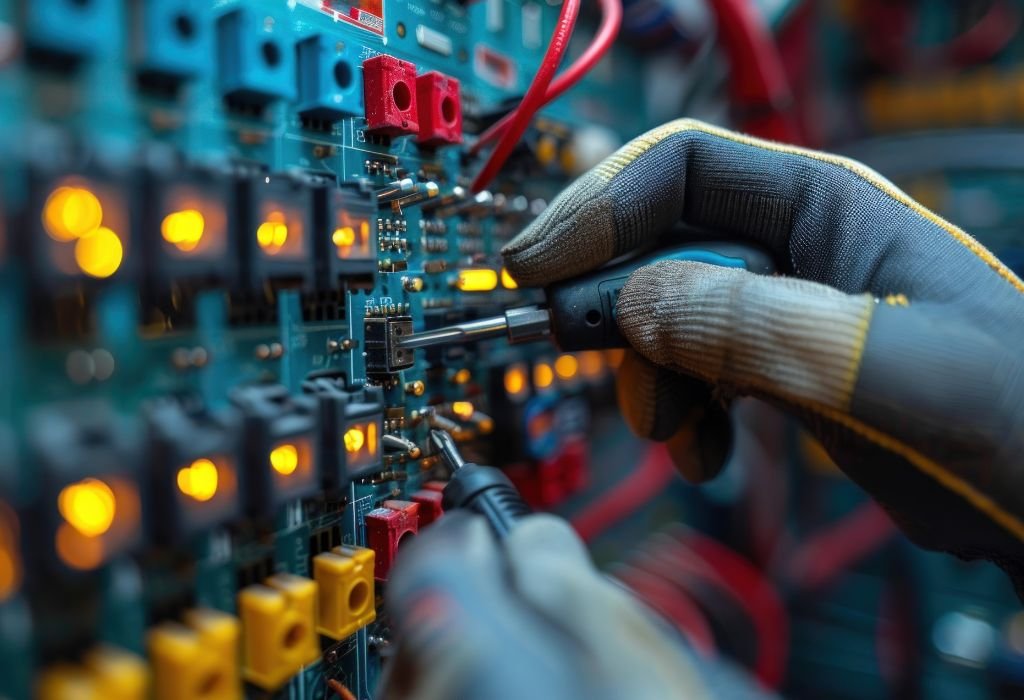

A technician stands in front of an open electrical panel, voltage tester in hand, wondering what type of gloves for electrical work will actually provide protection.

The wrong choice could mean severe shock, burns, or worse.

Confusion is common because different gloves serve different purposes. Some are designed to stop electric current, others protect from cuts, and some shield against arc flash heat.

Without clear guidance, workers may assume leather or fabric gloves are enough, when in fact only specific gloves are rated to withstand live voltage.

According to the U.S. Occupational Safety and Health Administration, electrical shock is a leading cause of workplace fatalities in construction and maintenance, responsible for more than 7% of all deaths in the sector (OSHA).

Voltage-rated rubber insulating gloves are the frontline defense against this hazard, and they must be paired with leather protector gloves to prevent punctures or cuts.

Standards such as ASTM D120 and NFPA 70E outline exact requirements, from glove classes based on voltage to in-service testing and inspection.

For example, Class 00 gloves are rated for up to 500 V AC, while Class 4 gloves withstand up to 36,000 V AC.

Choosing the correct class ensures that gloves provide real protection for the circuit being worked on.

This article breaks down exactly what type of gloves for electrical work should be used in different situations.

It explores OSHA and ASTM standards, explains voltage classes, compares rubber, leather, and arc-rated gloves, and offers practical inspection and buying advice.

By the end, you’ll know how to choose gloves that keep hands safe and compliant in any elThe Short Answer: What Type of Gloves for Electrical Work?

The safest choice for electrical work is voltage-rated rubber insulating gloves tested under ASTM D120 standards. These gloves are the only reliable barrier against electrical shock when working on energized circuits.

To prevent cuts, punctures, and abrasion damage, rubber gloves must be worn with leather protector gloves that meet ASTM F696 requirements. Without protectors, even a minor nick could render rubber gloves unsafe.

It is important not to confuse arc-rated gloves with voltage-rated gloves. Arc flash gloves protect against heat and burns but do not stop electric current from passing through.

Workers must always select the right class of glove based on the circuit voltage. For instance, Class 00 is rated for up to 500 V AC, while Class 2 is rated for 17,000 V AC.

What type of gloves for electrical work protect against shock?

Rubber insulating gloves paired with leather protectors provide certified shock protection.

Do arc-flash gloves replace rubber gloves?

No, arc-rated gloves protect from heat, not electrical current.

Are leather protectors optional?

Generally no — OSHA requires them, except in limited cases for Class 00 at ≤250 V AC where dexterity is critical.

How are glove classes determined?

By maximum use voltage, with classes ranging from 00 (500 V) to 4 (36,000 V).

Can ordinary leather or fabric gloves protect from electricity?

No, only voltage-rated rubber gloves are designed for shock protection.

Know the Standards: OSHA 1910.137, ASTM D120, NFPA 70E

OSHA 1910.137 requires workers exposed to electrical hazards to use rubber insulating gloves. It also defines testing, care, and protector glove rules.

ASTM D120 sets the performance standard for voltage-rated gloves, while ASTM F496 governs in-service testing intervals. ASTM F696 defines requirements for leather protectors.

NFPA 70E complements these standards by focusing on arc-flash risk assessments and PPE categories. Together, these rules form the foundation of safe electrical work.

What does OSHA 1910.137 require?

It mandates rubber insulating gloves and regular testing.

What is ASTM D120?

The standard for manufacturing and testing voltage-rated gloves.

How often are gloves tested?

Every 6 months or sooner if damaged.

Where does NFPA 70E fit?

It defines PPE categories for arc flash and shock hazards.

Do these standards overlap?

Yes, OSHA sets requirements, and ASTM defines the technical compliance.

Voltage Classes Explained (00–4): Pick by Circuit Voltage

Gloves are classified by the maximum use voltage they can safely handle. This ensures workers select PPE that matches the electrical system.

For example, Class 00 gloves protect up to 500 V AC, while Class 4 gloves protect up to 36,000 V AC. DC ratings are higher than AC ratings for each class.

Type I gloves are not ozone-resistant, while Type II gloves are ozone-resistant and last longer outdoors. Workers in polluted or high-ozone environments should select Type II.

What class do I need for 480 V AC?

Class 1 or higher, which covers up to 7,500 V AC.

Do DC voltages differ?

Yes, gloves have higher DC ratings compared to AC.

Type I vs Type II?

Type II resists ozone cracking better for outdoor use.

Is glove color coding standardized?

No, color varies by brand — always check markings.

How is class marked on gloves?

Each glove is stamped with the class, test date, and standards compliance.

Rubber Insulating Gloves vs Arc-Rated and Leather Protectors

Rubber insulating gloves provide shock protection but are easily damaged by cuts. Leather protectors prevent mechanical wear without reducing electrical resistance.

Arc-rated gloves protect against burns during an arc flash but do not provide shock protection. Workers facing both hazards must use rubber gloves with protectors and add arc-rated gloves where needed.

Why wear leather protectors?

They stop cuts and punctures that could ruin rubber gloves.

Can leather alone protect from shock?

No, leather is not voltage-rated.

Are arc-rated gloves enough?

No, they must be layered with rubber gloves when shock hazards exist.

Any OSHA exceptions?

Class 00 at ≤250 V AC may skip protectors for dexterity.

Do protectors reduce dexterity?

Slightly, but modern designs balance safety and usability.

Fit, Cuffs, and Sizing: Dexterity Without Sacrifice

Proper fit ensures safety and comfort. Gloves that are too tight may stretch and weaken, while loose gloves reduce dexterity.

Workers should measure their hand circumference and length before selecting a glove size. Cuff styles include straight, bell, and flare, with bell cuffs offering more room over sleeves.

How should voltage gloves fit?

Snug at the palm and fingers, without excessive stretching.

What cuff style is best for panels?

Bell cuffs, as they slide easily over sleeves.

Do protectors need to match glove size?

Yes, manufacturers provide pairing charts for each class.

Can liners be used for comfort?

Yes, but only those approved by manufacturers.

Do longer gloves offer more protection?

Yes, but they may reduce dexterity in confined spaces.

Inspection, Testing, and Storage

Gloves must be inspected before each use. Workers should perform an air test and look for cracks, cuts, or swelling.

ASTM F496 requires gloves to be tested every 6 months by an accredited lab. Gloves should be stored flat, clean, and away from sunlight, ozone, or petroleum products.

How to field-check gloves before use?

Roll them to trap air and listen for leaks.

How often must gloves be lab tested?

Every 6 months or after damage.

What damages gloves fastest?

Ozone, UV, sharp objects, and oil.

How should gloves be stored?

In protective glove bags, not folded or compressed.

What if gloves fail inspection?

They must be removed from service immediately.

Selecting by Task: Panels, Metering, Overhead Lines, EV Work

Different tasks require different glove classes. Panel work around 480 V AC typically requires Class 1 gloves, while overhead line work often demands Class 2 or higher.

Electric vehicle (EV) batteries may require Class 0 or Class 1 gloves, depending on pack voltage. Arc-flash gloves may also be required when thermal hazards are present.

What class for 277/480 V panels?

Class 1 gloves, covering up to 7,500 V AC.

Do I need sleeves too?

Yes, when within minimum approach distance.

For EV high-voltage systems?

Gloves must match the pack voltage rating.

When are arc-rated gloves required?

When arc-flash analysis shows thermal hazard risk.

Do utility workers need higher classes?

Yes, overhead distribution often requires Class 2 or above.

Common Mistakes and Myths

Many mistakes come from misunderstanding glove functions. Leather alone is not protective, and arc-rated gloves do not prevent shock.

Skipping leather protectors is another frequent error, as even a small puncture can make rubber gloves unsafe. Using petroleum-based cleaners also damages rubber.

Are Class 0 gloves OK for 600 V panels?

No, they are only rated to 1,000 V AC — Class 1 is safer.

Do cotton liners affect ratings?

Only if manufacturer-approved.

Can protectors touch live parts?

No, they are not shock-rated.

Is baby powder safe inside gloves?

No, only approved glove liners should be used.

Can damaged gloves be repaired?

No, they must be replaced.

Buying Guide: Brands, Kits, and Budgeting

When buying gloves, always look for the ASTM D120 marking, class rating, and valid test date. Many suppliers sell kits with rubber gloves, leather protectors, and a storage bag.

Type II gloves are recommended for outdoor and industrial use because they resist ozone cracking. Accessories such as glove bags and approved liners help extend glove life.

Should I buy new or recertified gloves?

Both are safe if test dates are valid.

Are Type II gloves worth the cost?

Yes, especially in outdoor work.

Can I mix glove and protector brands?

Yes, if properly sized and compliant.

What accessories matter most?

Glove bags, liners, and sleeves.

Do gloves expire?

Yes, check the stamped test date for compliance.

Future Trends in Electrical Work Gloves

Manufacturers are introducing gloves with improved dexterity, ergonomic leather protectors, and clearer labeling. Digital tracking tags for testing records are also emerging.

These innovations aim to reduce errors, improve comfort, and ensure compliance with safety standards.

Can new protectors improve dexterity?

Yes, modern designs are more ergonomic.

Will labeling get easier?

Yes, newer models feature clear laser-etched markings.

Are smart gloves on the horizon?

Yes, with QR codes for inspection logs.

Will lighter gloves reduce fatigue?

Yes, advanced compounds increase flexibility.

Is safety compliance improving?

Yes, innovations focus on usability and accountability.

Conclusion

So, what type of gloves for electrical work keep you safe? The answer is voltage-rated rubber insulating gloves that meet ASTM D120 standards, always worn with ASTM F696 leather protectors.

Arc-rated gloves may be added for burn protection, but they never replace rubber gloves for shock hazards. Glove class must always match the circuit voltage to ensure protection.

By following OSHA, ASTM, and NFPA guidelines, workers can select gloves that provide real safety, not false confidence. With the right pair, every technician can work knowing their hands are protected against the hidden dangers of electricity.

ectrical environment.

I’m Michael R. Turner, the founder, lead writer, and passionate DIY enthusiast behind 101diytools.com. With years of hands-on experience in home improvement and power tools, I built this platform to share practical tips, in-depth guides, and honest reviews to help DIYers of all skill levels tackle projects with confidence and the right tools.