Which Way Does a Circular Saw Blade Go? Expert Guide

Every DIYer has faced the frustration of rough, splintered cuts when using a circular saw. You measure, mark, and align perfectly, only to see the wood tear at the edges.

It’s a simple mistake that can ruin hours of work: the blade is spinning the wrong way. Many beginners aren’t sure which way a circular saw blade goes, leading to unsafe and inaccurate cuts.

A circular saw may seem straightforward, but understanding its rotation is critical for clean, professional results. Studies show that over 60% of DIY cutting mistakes come from improper blade direction or feed technique.

Even experienced woodworkers double-check blade orientation before important cuts to avoid kickback or damage. The correct spin ensures the teeth enter the wood smoothly and remove material efficiently.

By the end of this guide, you’ll know exactly which way a circular saw blade goes and how to use it safely on any project. With the right setup, technique, and attention to detail, clean cuts become effortless.

This article will cover saw types, rotation identification, cutting techniques, maintenance, troubleshooting, and FAQs to make you a confident, safe operator.

Understanding Circular Saw Basics

A circular saw consists of a motor, blade, and base plate that slides along the material. Knowing these components is essential to understanding how rotation affects cutting.

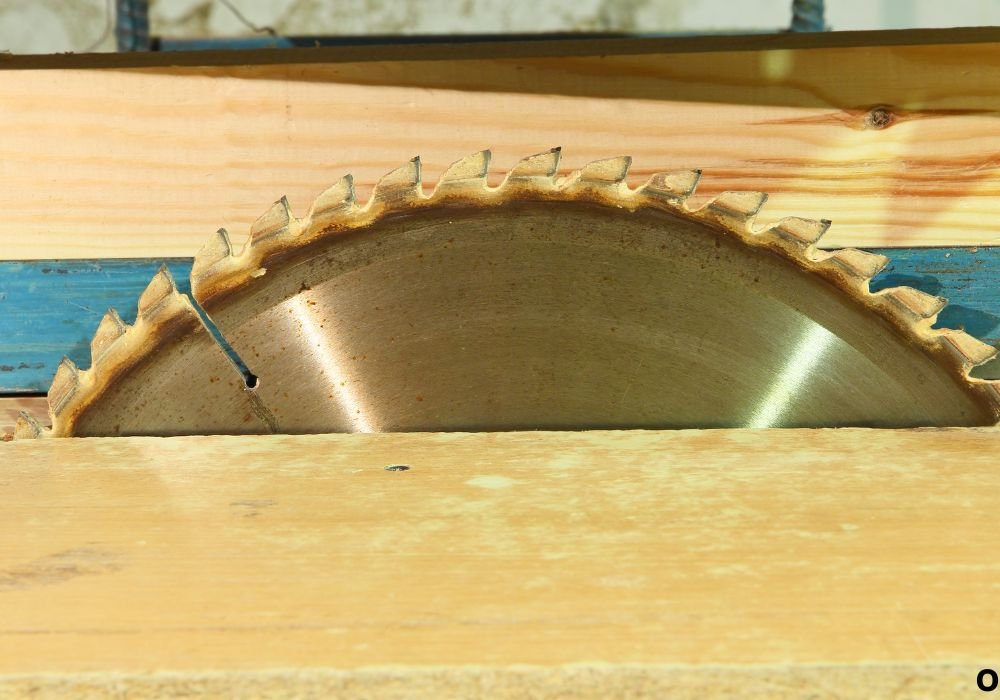

The blade is mounted on the arbor, which is powered by the motor. The rotation direction determines how the teeth engage the wood and remove material efficiently.

Most sidewinder saws rotate clockwise when viewed from the blade side, while worm-drive saws rotate counterclockwise. This difference affects cutting style and positioning.

Using the wrong rotation can lead to splintering, kickback, and uneven cuts. The correct blade orientation ensures safer operation and better results.

Beginners often overlook the rotation, assuming the saw is universally oriented. Taking the time to learn proper blade spin is one of the simplest ways to improve accuracy.

In addition to rotation, the blade type and teeth count play a role. Choosing a blade for the material ensures the motor isn’t overworked and the cut stays clean.

How to Identify Blade Rotation Direction

Most circular saws include arrows on the body or blade indicating rotation. Checking these before every cut can prevent mistakes and accidents.

Blades often have teeth angled forward in the rotation direction. Observing this angle helps ensure the teeth enter the wood correctly.

The saw’s manual is another reliable source for rotation details. It explains the correct installation method for different blade types.

Testing the saw briefly before cutting can verify rotation. A simple spin without pressure on the wood lets you see which way the teeth move.

Visual indicators on the blade and saw guard also guide proper orientation. Manufacturers place them to reduce confusion and enhance safety.

Paying attention to these cues prevents splintered edges, kickback, and unnecessary wear on the blade and motor. Proper observation is a small step that makes a big difference.

Types of Circular Saws and Blade Orientation

Sidewinder saws have the motor beside the blade and rotate clockwise. They are lighter, faster, and ideal for standard wood cutting.

Worm-drive saws have the motor behind the blade and rotate counterclockwise. They provide higher torque, making them suitable for thicker or harder materials.

Different materials require different blade orientation considerations. Wood, plywood, MDF, and metal each interact differently with rotation.

Using the right blade type improves efficiency. Fine-tooth blades work for clean cuts, while coarse teeth remove material faster but can splinter edges if misoriented.

Safety considerations vary per saw type. Worm-drive saws are heavier, so stability is essential during rotation verification.

Adjusting blade positioning for beveled or angled cuts ensures teeth engage correctly. Checking rotation before angled cuts prevents mishaps and uneven lines.

Cutting Techniques for Safety and Accuracy

Hold the saw firmly with both hands, aligning the base plate with the cut line. Correct grip reduces vibration and ensures smooth movement.

Feed material consistently in line with blade spin. Pushing against the rotation can cause kickback or splintering.

Angle cuts require slow, deliberate movement. The blade teeth should enter the wood gently to prevent tear-out.

Use guides, clamps, or fences whenever possible. They stabilize the material and provide a reference for straight cuts.

Avoid forcing the saw through thick material. Let the teeth cut naturally; forcing the blade increases the risk of injury and motor strain.

Beginner mistakes often include incorrect blade orientation or improper feed speed. Practicing on scrap wood helps build confidence and muscle memory.

Maintenance Tips to Keep Blades Correct

Regular cleaning removes resin and debris that reduce cutting efficiency. A clean blade spins smoothly and stays sharp longer.

Sharpen blades when teeth become dull. A dull blade increases resistance and may burn or tear the wood.

Check for chips, cracks, or warping before installation. Damaged blades compromise safety and performance.

Correct installation ensures the blade rotates in the right direction every time. Misalignment can cause uneven cuts and motor stress.

Lubrication is rarely needed, but storing blades in dry, safe locations prevents rust. Rusty blades are more prone to breakage.

Replacing worn or reversed blades keeps every cut precise. Maintaining blades extends the life of both the saw and the material being cut.

Troubleshooting Blade Rotation Issues

If the blade spins but doesn’t cut effectively, check teeth orientation and sharpness. Improper spin reduces cutting efficiency.

Excessive motor strain or overheating can indicate resistance due to dull blades or wrong rotation. Stop and inspect immediately.

Blade wobble or vibration suggests loose mounting or bent blades. Tighten the arbor nut and replace warped blades.

Some blades appear fine but are installed backwards. This causes rough cuts and increases kickback risk.

Replacement is safer than continuing to force a misaligned or damaged blade. Quality blades reduce maintenance headaches.

Following a pre-cut safety checklist ensures correct rotation, stable support, and protective gear for every project.

Frequently Asked Questions

What happens if the blade spins the wrong way?

The teeth won’t remove wood properly, causing splintering, kickback, and uneven cuts.

Can you reverse a circular saw blade?

No, blades are designed for a specific rotation direction; reversing may damage the blade and wood.

Do all circular saws spin the same way?

No, sidewinder saws usually rotate clockwise, while worm-drive saws rotate counterclockwise.

How do I know if my blade is installed correctly?

Check rotation arrows on the blade and saw body, and ensure teeth point forward in the rotation direction.

Can incorrect rotation damage the wood or saw?

Yes, it can tear material, overheat the motor, and shorten blade life.

How to cut metal safely with a circular saw?

Use a metal-cutting blade, slow feed, protective gear, and verify blade rotation before cutting.

Why do some blades have directional arrows?

They guide proper installation to ensure correct cutting and safety.

Tips for beginners on safe cutting?

Always check rotation, use clamps or guides, wear protective gear, and start with scrap wood practice.

What blade types require special attention?

Thin, fine-tooth, or specialty material blades need precise rotation for clean results.

Can kickback be prevented entirely?

No, but correct blade orientation, stable support, and careful feed reduce risks significantly.

Conclusion

Understanding which way a circular saw blade goes is crucial for safe, precise cutting. Proper rotation prevents splintering, kickback, and motor strain.

Always check the blade direction, read the manual, and verify the teeth angle before each cut. Correct blade selection and maintenance extend the life of your saw and material.

With practice, observing rotation cues, and following safety techniques, you’ll gain confidence in every cut. Knowing blade direction is the foundation of professional, clean woodworking.

I’m Michael R. Turner, the founder, lead writer, and passionate DIY enthusiast behind 101diytools.com. With years of hands-on experience in home improvement and power tools, I built this platform to share practical tips, in-depth guides, and honest reviews to help DIYers of all skill levels tackle projects with confidence and the right tools.